AERIAL CABLE-Guidelines for Pulling Fiber Optic Cables in Aerial Installations

Guidelines for Pulling Fiber Optic Cables in Aerial Installations

Main topics:

Best Practices for Pulling Fiber Optic Cables in Aerial Installations

In this article, we will explore the key considerations and techniques for pulling fiber optic cables in aerial installations.

Why Proper Cable Pulling Techniques Matter

Efficient and proper cable pulling techniques are essential for aerial installations of fiber optic cables. Without following the best practices, you may encounter several issues such as:

- Risk of cable damage: Fiber optic cables are delicate and vulnerable to excessive pulling forces. Improper pulling techniques can cause stress on the cable, leading to signal loss or even breakage.

- Reduced network performance: Cable damage or improper installation can result in signal degradation, affecting the overall network performance.

- Increased installation time and costs: If the cable gets damaged during the installation, it will require additional time and resources to repair or replace, leading to increased costs and delays in project completion.

Considerations Before Cable Pulling

Prior to cable pulling, it is crucial to consider the following aspects:

Cable Selection:

Choosing the right type of fiber optic cable is essential for aerial installations. Consider factors such as cable strength, flexibility, and resistance to UV radiation. Opt for cables specifically designed for outdoor applications, ensuring they meet industry standards and specifications.

Route Selection:

Identify the most suitable route for cable installation, taking into account any obstacles, environmental factors (like trees or buildings), and safety requirements. A detailed survey of the installation area will help in selecting the optimal path for the cables.

Best Practices for Cable Pulling

Follow these best practices to ensure a successful fiber optic cable installation:

Use a Cable Puller:

Invest in a cable pulling device that can handle the weight and tension requirements of the fiber optic cables. Use tension gauges to monitor and maintain proper pulling tension to prevent excessive force on the cables.

Keep Cable Bend Radius in Check:

One crucial aspect to consider during cable pulling is maintaining proper bend radius. Excessive bending can cause signal loss or cable damage. Follow the manufacturer's recommendations for minimum bend radius specifications.

Lubricate the Cable:

Applying a suitable lubricant on the cable can reduce friction and ease the cable pulling process. This prevents excessive stress on the cable and minimizes the chances of damage.

Protect Cable Ends:

Before and during the cable pulling process, make sure to properly protect the cable ends to avoid any contaminations or damages. Use dust caps or other suitable protective measures to secure the cable ends.

Ensure Proper Support:

Install adequate clamps, brackets, or supports to secure the cable along the aerial route. This prevents cable sag and reduces the risk of damage due to wind, ice, or other environmental factors.

Key Takeaways

Implementing proper techniques for pulling fiber optic cables in aerial installations is crucial to avoid damage, ensure network performance, and save time and costs. Remember the following key takeaways:

- Choose suitable fiber optic cables built for outdoor aerial installations.

- Select the optimal route considering obstacles and safety requirements.

- Invest in the right cable pulling equipment and maintain proper tension.

- Adhere to minimum bend radius specifications and use lubrication to ease the process.

- Protect cable ends and install proper support systems along the route.

By following these best practices, you can ensure a successful and efficient aerial installation of fiber optic cables, enabling reliable and fast data transmission in your network.

Choosing the Right Fiber Optic Cable for Aerial Installations

In this article, we will explore the key factors to consider when choosing a fiber optic cable for aerial installations and provide valuable insights to help you make an informed decision.

Fiber Optic Cable Types

Before delving into the selection process, it's essential to understand the different types of fiber optic cables available for aerial installations. Here are the primary cable types:

- Single-Mode Cable: Designed for long-distance transmission, single-mode cables have a smaller core size and can carry signals over vast distances without significant signal loss. They are ideal for intercity connectivity and long-haul applications.

- Multi-Mode Cable: Multi-mode cables are suitable for shorter distances due to higher signal attenuation. They feature a larger core size, enabling multiple light modes to propagate simultaneously. These cables are commonly used for local area networks (LAN) and data centers.

Depending on the specific requirements of your aerial installation project, you need to choose the appropriate fiber optic cable type to achieve optimal performance and efficiency.

Cable Strength and Durability

Aerial installations expose fiber optic cables to harsh environmental conditions such as wind, ice, and extreme temperatures. Therefore, selecting a cable with high tensile strength and durability is crucial. Consider the following factors:

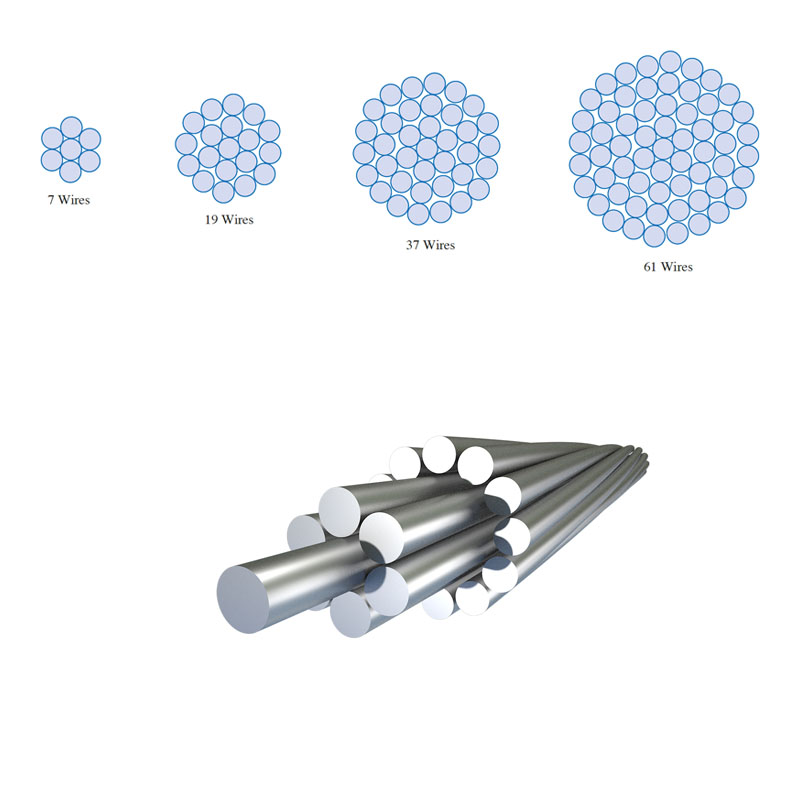

- Strength Members: Look for cables with aramid yarn or fiberglass rod strength members, as they provide excellent tensile strength to withstand the stress of aerial installations. These fibers help prevent cable sagging and damage.

- Jacket Material: Opt for cables with robust and weather-resistant jackets, such as polyethylene or polyurethane, which protect the fibers from moisture, UV radiation, and mechanical stress.

Ensuring the cable's strength and durability reduces the risk of cable failure and ensures reliable and uninterrupted data transmission.

Fiber Count and Capacity

Determining the required fiber count is vital when choosing a fiber optic cable for aerial installations. Consider both your current and future needs to avoid potential capacity limitations. Key aspects to consider include:

- Fiber Count: Assess the number of fibers required for your installation. It's advisable to opt for cables with extra fibers to accommodate potential future expansions, minimizing the need for additional installations.

- Capacity: Different cables offer varying capacities for transmitting data. Ensure that the chosen cable can handle the anticipated bandwidth requirements of your aerial installation project, both for current and future needs.

Choosing a cable with the right fiber count and capacity ensures scalability and future-proofing, saving you time and resources in the long run.

Ease of Installation

Efficiency in aerial installations is paramount to minimize deployment time and associated costs. When selecting a fiber optic cable, consider the ease of installation to streamline the process. Factors to evaluate include:

- Flexibility: Cables with increased flexibility allow for easier routing and shaping during installations, reducing the risk of damage or kinks.

- Pre-Connectorized Options: Some fiber optic cables come pre-connectorized, offering convenient plug-and-play capability, eliminating the need for additional time-consuming termination processes.

By choosing an easy-to-install fiber optic cable, you can significantly enhance the overall efficiency of your aerial installation project.

Key Takeaways

- Understanding the different fiber optic cable types - single-mode and multi-mode - is fundamental to choosing the right cable.

- Consider the strength, durability, and jacket material of the cable to ensure protection against environmental factors.

- Assess the required fiber count and capacity to accommodate both current and future needs.

- Evaluate the ease of installation, including factors like flexibility and pre-connectorized options, to streamline the deployment process.

In conclusion, selecting the appropriate fiber optic cable for aerial installations demands careful consideration of cable types, strength, fiber count, and ease of installation. By analyzing these vital factors, you can ensure a successful aerial installation that delivers optimal performance, reliability, and scalability for your data transmission needs.

Understanding Fiber Optic Cable Installation

Understanding how fiber optic cables are installed is essential for anyone involved in the telecommunications industry or those considering upgrading their internet connection. This article will provide an in-depth overview of fiber optic cable installation, its benefits, and key considerations for successful implementation.

The Basics of Fiber Optic Cables

Before delving into the details of fiber optic cable installation, it is important to understand the basics. Fiber optic cables are composed of tiny strands of glass or plastic called optical fibers. These fibers transmit digital information in the form of light pulses over long distances at incredibly high speeds. The cables are comprised of multiple fibers bundled together and protected by cable jackets to ensure durability and flexibility during installation.

- Faster Data Transmission: Fiber optic cables can transmit data at speeds nearly 100 times faster than traditional copper cables, offering lightning-fast internet speeds for businesses and households.

- Longer Transmission Distances: Fiber optic cables can transmit data over much longer distances without experiencing significant signal loss, making them ideal for long-haul telecommunications networks.

- Higher Bandwidth: Fiber optic cables have a much higher bandwidth capacity, allowing for the transmission of larger amounts of data simultaneously. This makes fiber optic connections ideal for handling multiple data-intensive applications simultaneously.

- Resistance to Interference: Unlike copper cables, fiber optic cables are immune to electromagnetic interference, providing a stable and reliable connection.

Fiber Optic Cable Installation Process

Successful fiber optic cable installation involves several key steps. These include planning, site preparation, cable routing, termination, and testing. Let's explore each step in detail:

Planning

Before embarking on any installation project, meticulous planning is crucial. The planning phase involves determining the required cable length, assessing the existing infrastructure, and understanding the network requirements. It is imperative to consider factors such as the number of fibers needed, desired data transmission rates, and potential areas of interference.

Site Preparation

Preparing the installation site is essential to ensure a smooth installation process. This may involve creating pathways for cable routing, installing necessary ducts or conduits, and ensuring proper cable management. Adequate ventilation and temperature control are also important to maintain optimal performance and longevity of the fiber optic cables.

Cable Routing

Proper cable routing is vital to minimize signal loss and maintain optimal performance. Fiber optic cables must be laid and secured along the designated pathway, keeping them clear of any sharp bends or obstructions. Care must be taken to prevent excessive tension or strain on the cables during installation, as this can lead to signal degradation.

Termination

Termination refers to the process of connecting the fiber optic cables to the necessary equipment, such as connectors or splices. This should be done accurately and securely to ensure minimal signal loss and reliable connectivity. Connectors and splices should be carefully selected based on the specific requirements of the network.

Testing

Thorough testing is essential to verify the integrity and performance of the installed fiber optic cables. Various tests, such as optical loss testing and continuity testing, are conducted to check for signal strength, data transmission quality, and potential faults or defects. These tests help identify and rectify any installation issues, ensuring optimal network performance.

- Accurate Planning: Proper planning ensures the installation meets network requirements, avoiding potential bottlenecks or future expansion limitations.

- Efficient Cable Routing: Careful cable routing minimizes signal loss, ensures optimal data transmission, and simplifies future maintenance or upgrades.

- Precision Termination: Accurate termination reduces signal loss and potential connectivity issues, ensuring reliable network performance.

- Thorough Testing: Comprehensive testing guarantees the integrity and performance of the installed fiber optic cables, reducing the need for subsequent troubleshooting or maintenance.

Conclusion

Understanding fiber optic cable installation is essential for anyone involved in the telecommunications industry or considering upgrading their internet connection. Fiber optic cables provide faster data transmission, longer distances, higher bandwidth, and resistance to interference, making them an ideal choice for modern networks. Successful installation involves meticulous planning, site preparation, cable routing, termination, and testing. By following these steps and considering the key advantages of fiber optic cables, organizations can ensure reliable and high-performance internet connectivity for their customers and employees.

Maintaining and Troubleshooting Aerial Fiber Optic Installations

Importance of Regular Maintenance

Maintaining aerial fiber optic installations is crucial for several reasons:

- Preventing Network Downtime: Regular maintenance procedures help identify and fix potential issues before they escalate into major problems, reducing the risk of network downtime.

- Optimizing Performance: Regular inspections and cleaning ensure that the fiber optic cables maintain optimal performance by minimizing signal loss and disruptions.

- Extending Lifespan: Proper maintenance helps extend the lifespan of the fiber optic installation, reducing the need for frequent replacements and saving costs.

Common Issues and Troubleshooting Techniques

Despite their reliability, aerial fiber optic installations can encounter problems. Here are a few common issues and effective troubleshooting techniques:

Physical Damage

Physical damage to fiber optic cables can occur due to various reasons, such as accidental cuts during construction work or animal interference. The following steps can help mitigate and fix physical damage:

- Inspect the damaged cable section for any visible cuts or breaks.

- If the damage is minimal, use a fusion splicer to join the fibers together.

- If the damage is severe or irreparable, replace the affected cable section.

- Implement proper protection measures, such as conduit installation or animal guards, to prevent future damage.

Signal Loss

Signal loss is a common issue in fiber optic installations and can be caused by numerous factors, including dirty connectors or excessive bend radius. The following techniques can help troubleshoot signal loss problems:

- Clean the connectors using lint-free swabs and isopropyl alcohol to remove any dirt or debris.

- Inspect and re-polish connectors if necessary.

- Check for excessive bends or kinks in the fiber optic cables. Replace cables with excessive bends and ensure proper cable management.

- Use OTDR (Optical Time Domain Reflectometer) equipment to identify any issues along the length of the fiber optic cables.

Environmental Factors

Environmental factors such as extreme temperatures, moisture, and exposure to chemicals can affect the performance of aerial fiber optic installations. Mitigate these issues with the following steps:

- Ensure fiber optic cables are properly secured using clamps or brackets to withstand wind and other weather conditions.

- Protect the cables from excessive moisture by using waterproof enclosures or heat shrink tubing.

- Keep the area surrounding the installations free from chemical exposure to prevent cable degradation.

Key Takeaways

Maintaining and troubleshooting aerial fiber optic installations is essential to ensure their optimal performance and longevity. Here are the key takeaways from this article:

- Regular maintenance helps prevent network downtime and optimize the performance of fiber optic installations.

- Physical damage to fiber optic cables can be repaired by splicing or replacing the damaged sections.

- Address signal loss issues by cleaning connectors, inspecting bends, and using OTDR equipment for identification.

- Mitigate environmental factors through proper cable protection and securing techniques.

- Proper maintenance and troubleshooting techniques save costs by extending the lifespan of aerial fiber optic installations.

By following these tips, you can ensure that your aerial fiber optic installations operate smoothly with minimal disruption. Stay proactive in maintaining your fiber optic network, and don't hesitate to seek assistance from professionals when needed!

Preparing for Aerial Fiber Optic Cable Installation

Aerial fiber optic cable installation is a popular method used by telecommunication companies to connect vast networks quickly and effectively.

Understanding Aerial Fiber Optic Cable Installation

Aerial fiber optic cable installation involves suspending fiber optic cables on utility poles or existing overhead infrastructure to establish the backbone of a network. This method offers several advantages, including the ability to cover long distances easily, rapid deployment, and cost-effectiveness. However, proper planning and preparation are crucial to ensure a successful installation process.

Key Takeaways:

- Reliable and high-speed internet connectivity is essential in today's world.

- Aerial fiber optic cable installation is a popular method for rapid network deployment.

- Proper planning and preparation are vital for successful installation.

Factors to Consider for Successful Aerial Fiber Optic Cable Installation

Before embarking on an aerial fiber optic cable installation project, it is essential to consider the following factors:

- Route Planning: Determine the most efficient and effective path for the cable installation. Consider factors such as existing infrastructure, population density, and potential obstacles that could hinder the installation process.

- Permits and Regulations: Understand and comply with local regulations and obtain the necessary permits for aerial cable installation. This step ensures legal compliance and mitigates any potential disruptions during the installation process.

- Safety Measures: Prioritize safety during the installation process. Ensure that all technicians involved are fully trained on safety protocols and equipped with appropriate personal protective equipment (PPE).

- Weather Conditions: Take into account weather conditions, especially those that may pose hazards to the aerial installation process, such as strong winds, storms, or lightning. Plan installation activities accordingly to minimize risk.

- Cable Specifications: Select the appropriate fiber optic cable that meets the specific requirements of the project. Consider factors like cable capacity, signal quality, and durability.

Advantages of Aerial Fiber Optic Cable Installation:

- Rapid network deployment to connect vast areas quickly.

- Cost-effective compared to underground cable installation.

- Access to existing infrastructure reduces construction time and costs.

- Easy maintenance and repair due to accessibility.

Best Practices for Aerial Fiber Optic Cable Installation

Follow these best practices to ensure a smooth and successful aerial fiber optic cable installation:

- Thorough Site Survey: Conduct a comprehensive site survey to identify any potential obstacles or hazards that may impact the installation process. This includes assessing the condition of utility poles, clearance requirements, and identifying the most suitable anchoring points.

- Secure Attachment Points: Ensure that all attachment points, such as utility poles or existing infrastructure, are structurally sound and capable of supporting the weight and tension of the fiber optic cables. Use appropriate hardware and techniques to secure the cables, such as tension clamps or suspension brackets.

- Proper Cable Sag: Maintain the optimal sag in the aerial cables to prevent excessive tension, which could degrade signal quality or cause cable damage. Follow industry standards and guidelines for calculating the appropriate sag based on factors like span length, cable weight, and environmental conditions.

- Protective Measures: Implement protective measures to safeguard aerial fiber optic cables from external factors such as bird interference, potential vandalism, or accidental damage. Consider using protective enclosures or applying coatings that enhance durability.

- Documentation and Testing: Document all stages of the cable installation process and perform thorough testing to ensure proper connectivity and signal quality. Maintain comprehensive records for future reference and troubleshooting.

Key Takeaways:

- Thorough site survey and secure attachment points are crucial for successful installation.

- Maintaining proper cable sag is important to prevent signal degradation or cable damage.

- Implement protective measures to safeguard aerial fiber optic cables.

- Document all stages and perform comprehensive testing for optimal connectivity.

In conclusion, preparing for aerial fiber optic cable installation requires careful planning, adherence to regulations, and implementation of safety measures. By considering factors such as route planning, permits, safety, weather conditions, and cable specifications, organizations can ensure a successful installation process. Aerial installations offer advantages such as rapid deployment, cost-effectiveness, and easy maintenance. Following best practices, including a thorough site survey, secure attachment points, proper cable sag, protective measures, and comprehensive documentation and testing, will further contribute to a successful and reliable fiber optic cable installation.

-

Reliable LIYCY Cable Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Premium Overhead Electrical Wire Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Innovative XLPE Electrical Cable Solutions for Modern Low and Medium Voltage NetworksNewsJul.14,2025

-

High-Quality Ethylene Propylene Rubber Cable – Durable EPDM Cable & 1.5 mm 3 Core OptionsNewsJul.14,2025

-

Exploring the Versatility of H1Z2Z2-K 1X4mm2 Cables in Modern ApplicationsNewsJul.14,2025

-

Uses of Construction WiresNewsJul.14,2025

-

Types of Neoprene CableNewsJul.14,2025