Imagine when we give instructions in an automation system, how can we ensure that the information is accurately executed? In which the most critical transmission component is the control cable. Control cables are multi-core cables for automation and instrumentation applications that measure and regulate the transmission of automated processes.

Why control cable is so vital? This article will detail the specifications, types, sizes, and colors of controlling cables and how they differ from electrical cables.

What is control cable?

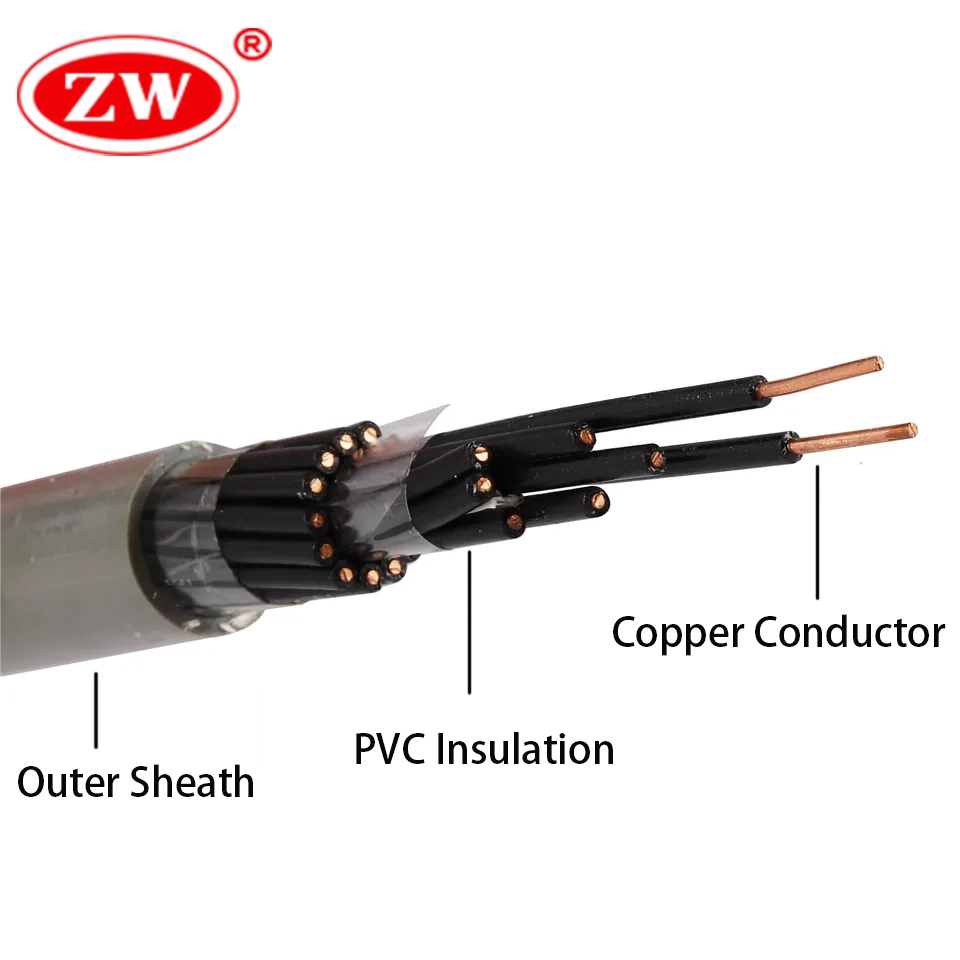

Control electrical cable is a type of flexible mechanical cable used to relay control signals or forces from the system to the specific control point; which are commonly used in various applications requiring precise control and manipulation, such as industrial automation, robots, and CNC machine tools. In consideration of precise control and downtime costs, the requirements for electrical control cables are more stringent than other types of cables, which need to be characterized by stable transmission and strong resistance to electromagnetic interference. For this reason, control wires are made up of multi-stranded or single copper conductors insulated with PVC or low smoke zero halogen (LSZH), and some sizes of cables are shielded with braided copper wire to minimize interference.

nothing found.

Control wires play a vital role in regulating processes, ensuring the proper functioning of machinery, and maintaining communication between control devices and sensors. Known for their reliability, and flexibility, they can operate at temperatures up to 80℃. And depending on the specific application, there are different variants of control wires to suit different requirements, such as push-pull control cables for vehicle throttle control (throttle control cable), and access control cables for security access control systems.

2XSLH 0.6/1kV Cu Conductors with XLPE Insulated and with Low Smoke Zero Halogen Sheathed Control Cable

Below we talk specifically about the most common types summarized from the controlling cable variants.

What are control cable types?

Understanding the types of control wires is critical to choosing the right one for the given task. The most common types are:

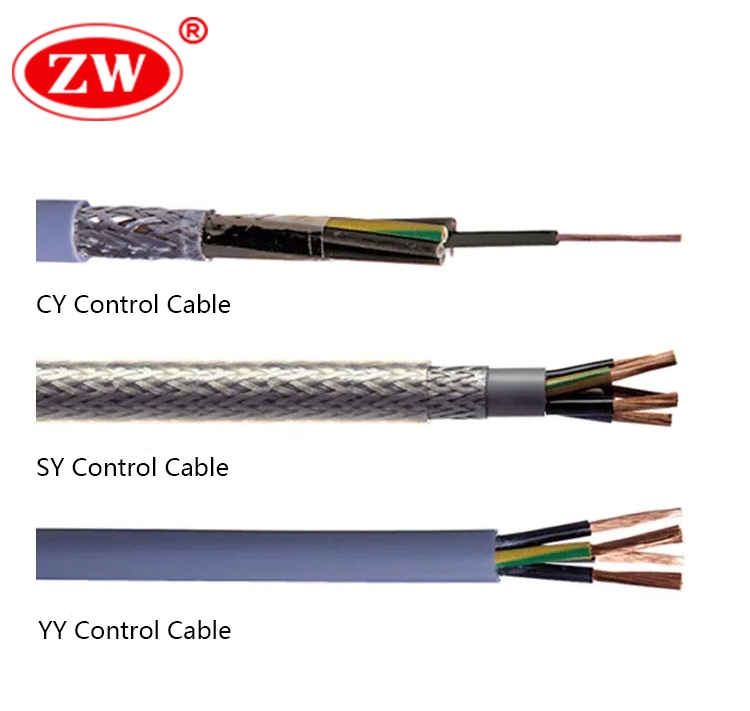

CY Cable: CY cables are shielded flexible cables. They feature a tinned copper braid shield around the cable core to provide protection against electromagnetic interference (EMI) and radio frequency interference (RFI), commonly used for interference-free transmission, maintaining signal integrity.

SY Cable: SY cables are flexible control electrical cables, similar to CY cables, but containing galvanized steel braided for mechanical protection and adopting a transparent PVC sheath for easy viewing of internal wear or damage. Typically applications contain garden lighting, pond pumps, and other applications where resistance to high levels of stress without a loss of flexibility is required.

YY Cable: YY cables are unshielded flexible controlling cables. They do not have shielding for protection but are cost-effective and versatile. YY cables are used in general-purpose applications where EMI/RFI interference is not a concern, such as control panels, instrumentation, and lighting systems.

Whether you need to control machinery, transmit electronic signals, or for the reliable operation of vehicles, choosing the right type is a priority. Moreover, the size of the control electrical wire is also a pivotal element in determining whether the application can be operated safely or not.