Why Wires?

Why Wires?

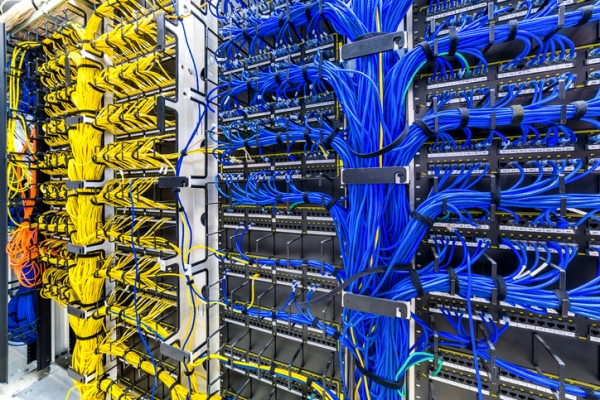

Think about all the wires that you use every day. Wires are a big part of our lives, even if we don’t always realize it. Electrical wiring, guitar strings, and paper clips are just a few examples of wires. Even the Internet is made up of a lot of computers connected by wires. Wires are such a regular presence in our lives that we don’t always think about.

What are wires made out of?

Wires are made from metals. Some of the metals used include steel, copper, aluminum, and silver. We use these materials to make wires because of their properties. Metals have a high melting point and are usually a solid at room temperature. They are also ductile. This means that they can be easily stretched. Finally, metals are good conductors of heat and electricity. This means electricity and heat can easily flow through them.

Did you know?

Silver is the element that is best at conducting electricity.

How are wires made?

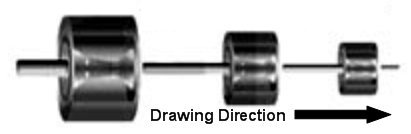

Wire drawing is a process that is often used to make wires. Drawing wires involves reducing the diameter of metal rods to the desired diameter. Diameter is another word for the width of a circle or cylinder. Wire gauge is a measurement of a wire’s diameter. The wire drawing process can produce many different sizes of wire. Let’s see how it works.

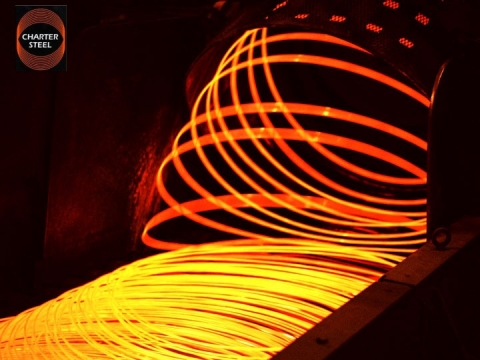

First, a piece of steel, called a billet, is heated to about 2000°C. This makes it easier to change its shape. The hot billet is fed through a series of rolling stands which turn the metal into a rod that is 1-4 cm in diameter. The rod is then formed into coils.

The coils are left outdoors to cool. Each coil weighs about 700-900 kg! The coils can develop some surface rust and get dirty during storage. This must be cleaned off before the next step. Cleaning involves dipping the coil in a hot water solution with chemicals that removes any surface dirt.

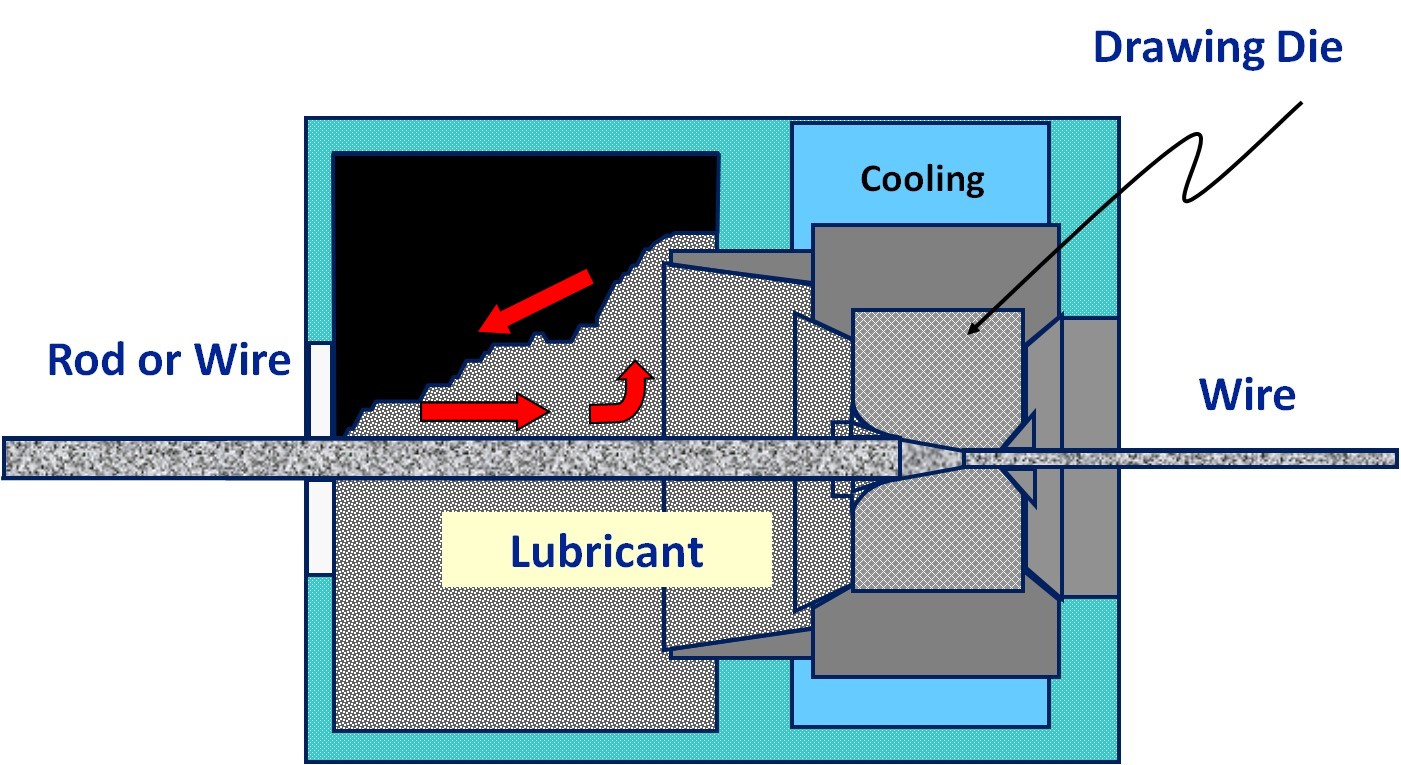

The rod is then passed into through a series of lubricated dies. A lubricant is a material that makes something slippery. Oil is often used as a lubricant. A die is a tool that is used to press, cut, or shape a material. Here, dies reduce the large diameter of the rod to smaller diameter wire. Wires can withstand the force of this process because they are very ductile. A less ductile material, like glass, would shatter.

60227 IEC 03 STANDARD 300/500V BV-90 H05V-U NYA SOLID COPPER BUILDING WIRE

Eventually, thin wires are formed. Lubricants, such as the ones manufactured by Blachford Chemical Group*, reduce friction and provide a barrier as the wire passes through the die. Lubricants make the process go faster and help the dies to last longer.

*Refers to Blachford Corporation and H.L. Blachford Ltd.

For drawing steel wire, the lubricant is a powder. The die box is filled with the powder and the wire is pulled first through the powder and then through the die. The die has a cone at the front. Its decreasing diameter forces a coating of the lubricant onto the wire. The finished wire will have a light lubricant film left on it and may require cleaning before further processing into end products.

This process can create dust. This dust can be a dust explosion hazard. This is why it is important to control dust in a wire drawing operation.

How do we use wires?

People use wires to create many other products. For example, nuts and bolts are made from steel wire. Wire drawn to a specific diameter is then pressed into the shape of a bolt or screw. The lower section is then threaded to create a spiral. Nails are also made from wire sections that are flattened on one end and sharpened at the other end.

Drawn wires are also used to make common items such as staples for paper staplers. In this case, a very thin wire is passed through a square die, rather than a round one, to give the final shape. It is then cut, bent and in some cases sharpened into the finished product. Paper clips are also made of wire formed into their classic shape.

Some guitar strings are made of pieces of steel wire. The wires are drawn to different diameters and strengths. Banjos and pianos also use wire. Other examples of steel products manufactured from wire are shelving, fencing, welding wire and syringe needles.

Some wires carry electricity. These wires are often made from copper or aluminum. Wires of different sizes carry different types and amounts of electricity. A wire’s gauge determines how much electric current it can carry. Cables are groups of wires bundled together. Wires that carry electricity are wrapped in an insulator, such as plastic. The insulation keeps people from getting shocked. It also makes sure the electricity flows to the right place.

Wire is also used to make jewelry, such as earrings. Silver and gold wires are formed using a similar process as the one described above. However, they are often drawn by hand and created on a smaller scale.

These are just a few of the many ways that we use wires. Next time you plug in your computer or use a paperclip, think about all of the steps that went into creating it.

Let’s Talk Science appreciates the work and contributions of H.L Blachford Ltd. in the development of this Backgrounder.

-

Reliable LIYCY Cable Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Premium Overhead Electrical Wire Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Innovative XLPE Electrical Cable Solutions for Modern Low and Medium Voltage NetworksNewsJul.14,2025

-

High-Quality Ethylene Propylene Rubber Cable – Durable EPDM Cable & 1.5 mm 3 Core OptionsNewsJul.14,2025

-

Exploring the Versatility of H1Z2Z2-K 1X4mm2 Cables in Modern ApplicationsNewsJul.14,2025

-

Uses of Construction WiresNewsJul.14,2025

-

Types of Neoprene CableNewsJul.14,2025