Afrikaans Albanian Amharic Arabic Armenian Azerbaijani Basque Belarusian Bengali Bosnian Bulgarian Catalan Cebuano China Corsican Croatian Czech Danish Dutch English Esperanto Estonian Finnish French Frisian Galician Georgian German Greek Gujarati Haitian Creole hausa hawaiian Hebrew Hindi Miao Hungarian Icelandic igbo Indonesian irish Italian Japanese Javanese Kannada kazakh Khmer Rwandese Korean Kurdish Kyrgyz Lao Latin Latvian Lithuanian Luxembourgish Macedonian Malgashi Malay Malayalam Maltese Maori Marathi Mongolian Myanmar Nepali Norwegian Norwegian Occitan Pashto Persian Polish Portuguese Punjabi Romanian Russian Samoan Scottish Gaelic Serbian Sesotho Shona Sindhi Sinhala Slovak Slovenian Somali Spanish Sundanese Swahili Swedish Tagalog Tajik Tamil Tatar Telugu Thai Turkish Turkmen Ukrainian Urdu Uighur Uzbek Vietnamese Welsh Bantu Yiddish Yoruba Zulu

Jun . 23, 2024 06:36

Back to list

Top 10 Rubber Cable Manufacturers Global Industry Leaders

An Insight into the World of HO7 Rubber Cable Factories

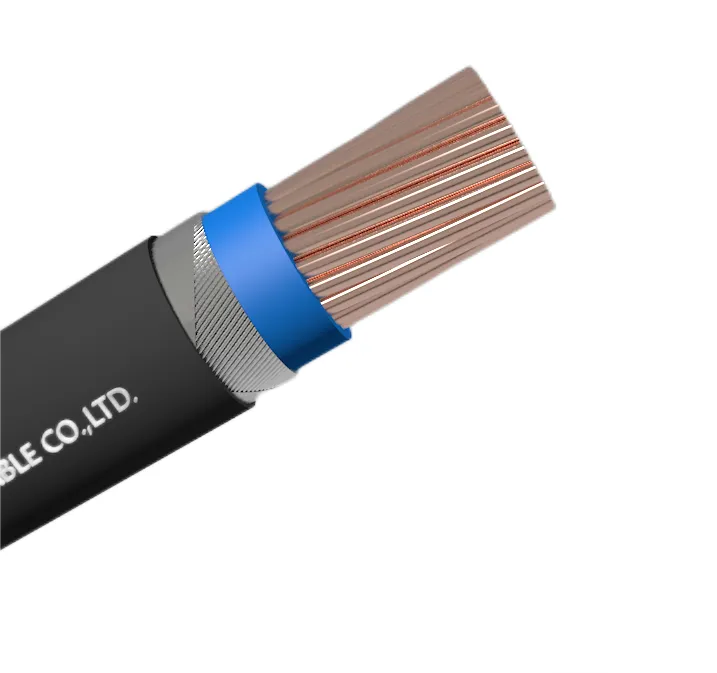

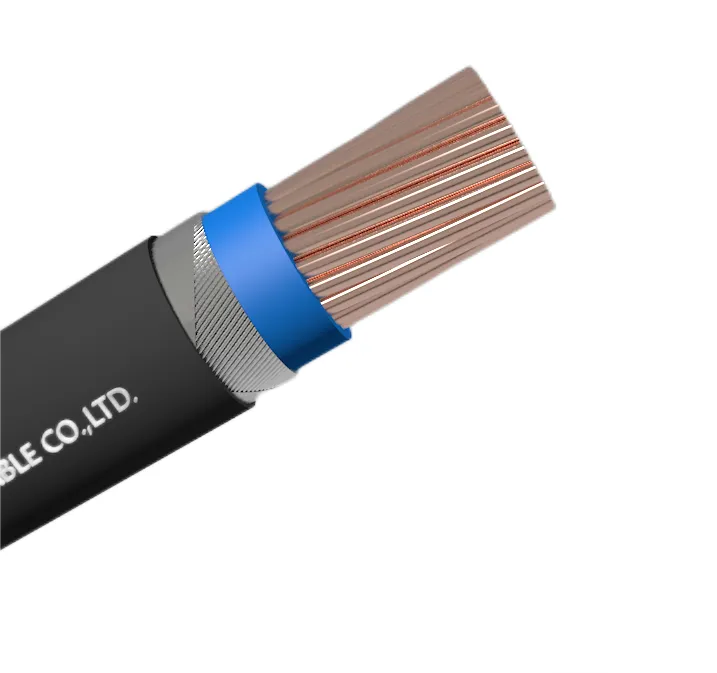

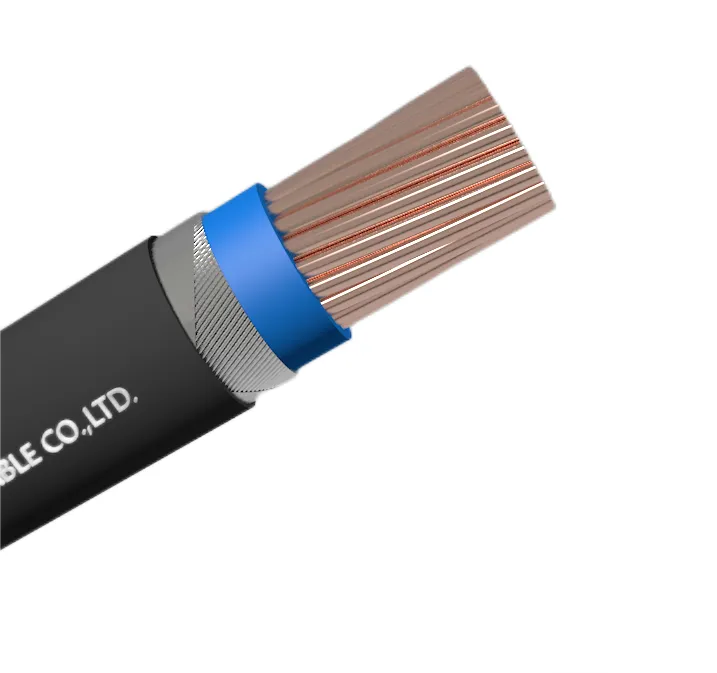

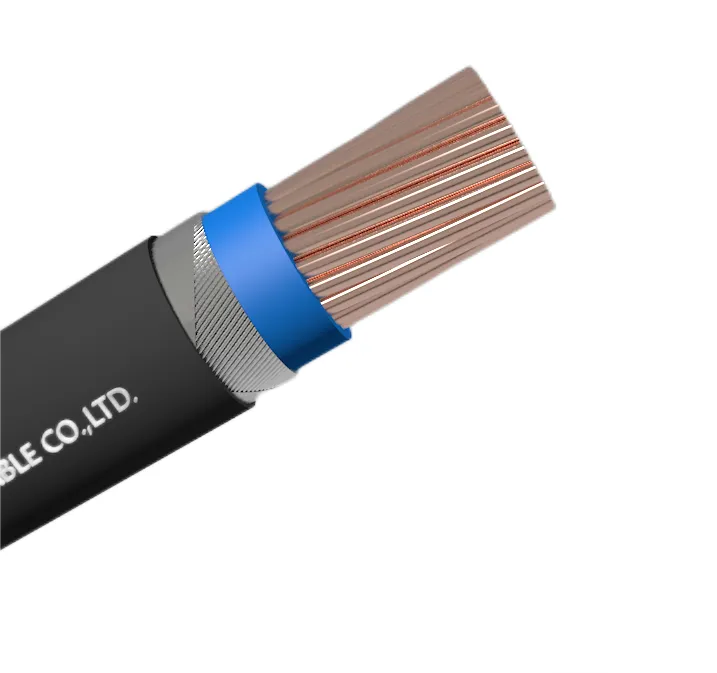

In the vast landscape of industrial manufacturing, HO7 rubber cables hold a significant position due to their robustness and versatility. These cables, primarily designed for heavy-duty applications, find usage in various sectors such as construction sites, industrial plants, and outdoor events. The factories that specialize in producing HO7 rubber cables are the backbone of this niche industry.

HO7 stands for 'Heavily Overloaded 7', referring to its seven conductor wires that can withstand high mechanical stress and extreme environmental conditions. The rubber insulation makes them resistant to water, oil, chemicals, and even flames, making them ideal for demanding environments.

The production process in a typical HO7 rubber cable factory is a blend of precision engineering and meticulous craftsmanship. It begins with the selection of high-quality raw materials, including copper for conductors and specialized rubber compounds for insulation and sheathing. These materials undergo rigorous quality checks to ensure they meet industry standards.

Once the materials pass the inspection, they are processed through specialized machinery that forms and insulates the individual wires. The wires are then assembled into a multi-core cable and subjected to a vulcanization process, which fuses the rubber components together, enhancing the cable's durability and flexibility. Post-vulcanization, the cables undergo further testing for electrical integrity, tensile strength, and resistance to various environmental factors.

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States ho7 rubber cable factories. Each factory has its unique production techniques, often incorporating cutting-edge technology for increased efficiency and productivity. For instance, some factories use automated systems for cable laying and testing, while others rely on skilled human labor for the intricate tasks.

These factories not only contribute to the global supply chain but also play a crucial role in local economies by providing employment opportunities and fostering technological advancements. They adhere to stringent safety and environmental regulations, ensuring sustainable and responsible manufacturing practices.

However, the industry faces challenges, including the need for constant innovation to meet evolving safety standards and the demand for eco-friendly materials. Factories are investing in research and development to produce cables with better performance characteristics and reduced environmental impact.

In conclusion, HO7 rubber cable factories are integral to the infrastructure and industrial sectors, providing essential components for power transmission in challenging conditions. Their commitment to quality, safety, and innovation ensures that these cables continue to serve their purpose effectively, making them indispensable in numerous industries worldwide. As technology advances and sustainability becomes a focal point, these factories will continue to evolve, shaping the future of cable manufacturing.

ho7 rubber cable factories. Each factory has its unique production techniques, often incorporating cutting-edge technology for increased efficiency and productivity. For instance, some factories use automated systems for cable laying and testing, while others rely on skilled human labor for the intricate tasks.

These factories not only contribute to the global supply chain but also play a crucial role in local economies by providing employment opportunities and fostering technological advancements. They adhere to stringent safety and environmental regulations, ensuring sustainable and responsible manufacturing practices.

However, the industry faces challenges, including the need for constant innovation to meet evolving safety standards and the demand for eco-friendly materials. Factories are investing in research and development to produce cables with better performance characteristics and reduced environmental impact.

In conclusion, HO7 rubber cable factories are integral to the infrastructure and industrial sectors, providing essential components for power transmission in challenging conditions. Their commitment to quality, safety, and innovation ensures that these cables continue to serve their purpose effectively, making them indispensable in numerous industries worldwide. As technology advances and sustainability becomes a focal point, these factories will continue to evolve, shaping the future of cable manufacturing.

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States

HO7 rubber cable factories operate on a global scale, with major players located in countries like China, Germany, Italy, and the United States ho7 rubber cable factories. Each factory has its unique production techniques, often incorporating cutting-edge technology for increased efficiency and productivity. For instance, some factories use automated systems for cable laying and testing, while others rely on skilled human labor for the intricate tasks.

These factories not only contribute to the global supply chain but also play a crucial role in local economies by providing employment opportunities and fostering technological advancements. They adhere to stringent safety and environmental regulations, ensuring sustainable and responsible manufacturing practices.

However, the industry faces challenges, including the need for constant innovation to meet evolving safety standards and the demand for eco-friendly materials. Factories are investing in research and development to produce cables with better performance characteristics and reduced environmental impact.

In conclusion, HO7 rubber cable factories are integral to the infrastructure and industrial sectors, providing essential components for power transmission in challenging conditions. Their commitment to quality, safety, and innovation ensures that these cables continue to serve their purpose effectively, making them indispensable in numerous industries worldwide. As technology advances and sustainability becomes a focal point, these factories will continue to evolve, shaping the future of cable manufacturing.

ho7 rubber cable factories. Each factory has its unique production techniques, often incorporating cutting-edge technology for increased efficiency and productivity. For instance, some factories use automated systems for cable laying and testing, while others rely on skilled human labor for the intricate tasks.

These factories not only contribute to the global supply chain but also play a crucial role in local economies by providing employment opportunities and fostering technological advancements. They adhere to stringent safety and environmental regulations, ensuring sustainable and responsible manufacturing practices.

However, the industry faces challenges, including the need for constant innovation to meet evolving safety standards and the demand for eco-friendly materials. Factories are investing in research and development to produce cables with better performance characteristics and reduced environmental impact.

In conclusion, HO7 rubber cable factories are integral to the infrastructure and industrial sectors, providing essential components for power transmission in challenging conditions. Their commitment to quality, safety, and innovation ensures that these cables continue to serve their purpose effectively, making them indispensable in numerous industries worldwide. As technology advances and sustainability becomes a focal point, these factories will continue to evolve, shaping the future of cable manufacturing. Latest news

-

The Quantum Leap of XLPE Cable in Power DistributionNewsMay.29,2025

-

Mastering the Essentials of Building WireNewsMay.29,2025

-

Innovative Horizons of Rubber Trailing CablesNewsMay.29,2025

-

Exploring the Versatile World of Rubber CablesNewsMay.29,2025

-

Decoding the Mysteries of Building CablesNewsMay.29,2025

-

Advancements Redefining Control Cable TechnologyNewsMay.29,2025

-

Why It's Time to Replace Old Rubber CablesNewsMay.28,2025

Related PRODUCTS