Afrikaans Albanian Amharic Arabic Armenian Azerbaijani Basque Belarusian Bengali Bosnian Bulgarian Catalan Cebuano China Corsican Croatian Czech Danish Dutch English Esperanto Estonian Finnish French Frisian Galician Georgian German Greek Gujarati Haitian Creole hausa hawaiian Hebrew Hindi Miao Hungarian Icelandic igbo Indonesian irish Italian Japanese Javanese Kannada kazakh Khmer Rwandese Korean Kurdish Kyrgyz Lao Latin Latvian Lithuanian Luxembourgish Macedonian Malgashi Malay Malayalam Maltese Maori Marathi Mongolian Myanmar Nepali Norwegian Norwegian Occitan Pashto Persian Polish Portuguese Punjabi Romanian Russian Samoan Scottish Gaelic Serbian Sesotho Shona Sindhi Sinhala Slovak Slovenian Somali Spanish Sundanese Swahili Swedish Tagalog Tajik Tamil Tatar Telugu Thai Turkish Turkmen Ukrainian Urdu Uighur Uzbek Vietnamese Welsh Bantu Yiddish Yoruba Zulu

Jun . 14, 2024 00:06

Back to list

Request for cable estimates ePR, PCP, and associated costs.

Understanding EPR, PCP, and Cable Quotes A Comprehensive Guide

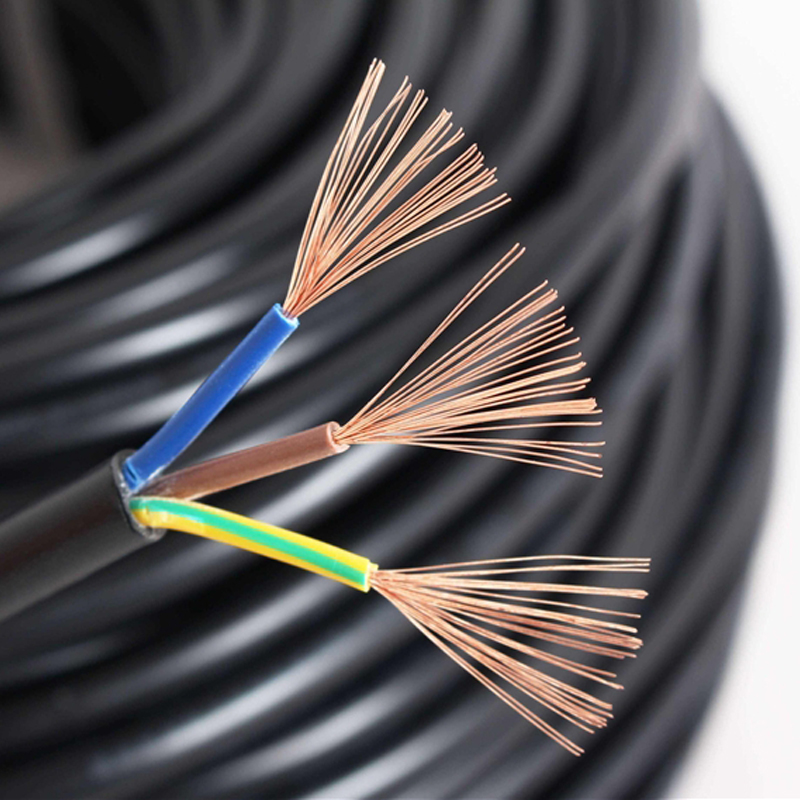

In the world of telecommunications and cable infrastructure, understanding technical jargon is crucial for making informed decisions. Two key terminologies that often come up in discussions are EPR (Ethylene Propylene Rubber) cables and PCP (Pre-Crushed Polypropylene). These materials play a significant role in cable manufacturing, influencing not only performance but also the cost estimates or quotes provided by suppliers. Let's delve into these concepts and their relevance in the industry.

EPR, or Ethylene Propylene Rubber, is a type of synthetic rubber widely used as an insulation material in high-voltage power cables. It offers excellent electrical properties, thermal stability, and resistance to weathering, chemicals, and aging. EPR cables are known for their flexibility, which makes them ideal for installation in tight spaces or where frequent bending is required. Their superior dielectric strength and low loss characteristics make them a preferred choice in demanding applications, contributing to their relatively higher quotes compared to other insulation materials.

On the other hand, PCP, or Pre-Crushed Polypropylene, refers to a process used in cable manufacturing. In this method, polypropylene is crushed before being utilized as a sheathing material. This pre-crushing step allows for better compaction during extrusion, resulting in a more compact cable with enhanced mechanical strength and improved resistance to environmental stresses. The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved

The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved epr pcp cable quotes.

When it comes to cable quotes, several factors are considered, including the type of insulation and sheathing material, cable size, length, and the specific application requirements. EPR cables, with their superior performance attributes, generally command a premium price compared to alternatives like PVC or XLPE cables. Similarly, the inclusion of PCP sheathing may increase the quote due to its enhanced durability and resilience.

Understanding the implications of EPR and PCP in cable design is vital for estimating project costs accurately. While initial quotes might be higher, the long-term benefits such as increased durability, reduced maintenance, and improved performance often justify the investment. It's essential to work closely with suppliers to evaluate the total cost of ownership, considering both the upfront cost and the potential savings over the cable's lifespan.

In conclusion, EPR and PCP are integral components in cable technology, each bringing its unique advantages to the table. While they may impact cable quotes, their value lies in the performance enhancement and longevity they provide. When evaluating cable quotes, it's crucial to weigh these factors against the specific needs of your project to make an informed decision.

epr pcp cable quotes.

When it comes to cable quotes, several factors are considered, including the type of insulation and sheathing material, cable size, length, and the specific application requirements. EPR cables, with their superior performance attributes, generally command a premium price compared to alternatives like PVC or XLPE cables. Similarly, the inclusion of PCP sheathing may increase the quote due to its enhanced durability and resilience.

Understanding the implications of EPR and PCP in cable design is vital for estimating project costs accurately. While initial quotes might be higher, the long-term benefits such as increased durability, reduced maintenance, and improved performance often justify the investment. It's essential to work closely with suppliers to evaluate the total cost of ownership, considering both the upfront cost and the potential savings over the cable's lifespan.

In conclusion, EPR and PCP are integral components in cable technology, each bringing its unique advantages to the table. While they may impact cable quotes, their value lies in the performance enhancement and longevity they provide. When evaluating cable quotes, it's crucial to weigh these factors against the specific needs of your project to make an informed decision.

The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved

The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved The use of PCP can lead to a more durable cable, albeit with a potentially higher quote due to the additional processing involved epr pcp cable quotes.

When it comes to cable quotes, several factors are considered, including the type of insulation and sheathing material, cable size, length, and the specific application requirements. EPR cables, with their superior performance attributes, generally command a premium price compared to alternatives like PVC or XLPE cables. Similarly, the inclusion of PCP sheathing may increase the quote due to its enhanced durability and resilience.

Understanding the implications of EPR and PCP in cable design is vital for estimating project costs accurately. While initial quotes might be higher, the long-term benefits such as increased durability, reduced maintenance, and improved performance often justify the investment. It's essential to work closely with suppliers to evaluate the total cost of ownership, considering both the upfront cost and the potential savings over the cable's lifespan.

In conclusion, EPR and PCP are integral components in cable technology, each bringing its unique advantages to the table. While they may impact cable quotes, their value lies in the performance enhancement and longevity they provide. When evaluating cable quotes, it's crucial to weigh these factors against the specific needs of your project to make an informed decision.

epr pcp cable quotes.

When it comes to cable quotes, several factors are considered, including the type of insulation and sheathing material, cable size, length, and the specific application requirements. EPR cables, with their superior performance attributes, generally command a premium price compared to alternatives like PVC or XLPE cables. Similarly, the inclusion of PCP sheathing may increase the quote due to its enhanced durability and resilience.

Understanding the implications of EPR and PCP in cable design is vital for estimating project costs accurately. While initial quotes might be higher, the long-term benefits such as increased durability, reduced maintenance, and improved performance often justify the investment. It's essential to work closely with suppliers to evaluate the total cost of ownership, considering both the upfront cost and the potential savings over the cable's lifespan.

In conclusion, EPR and PCP are integral components in cable technology, each bringing its unique advantages to the table. While they may impact cable quotes, their value lies in the performance enhancement and longevity they provide. When evaluating cable quotes, it's crucial to weigh these factors against the specific needs of your project to make an informed decision. Latest news

-

Reliable LIYCY Cable Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Premium Overhead Electrical Wire Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Innovative XLPE Electrical Cable Solutions for Modern Low and Medium Voltage NetworksNewsJul.14,2025

-

High-Quality Ethylene Propylene Rubber Cable – Durable EPDM Cable & 1.5 mm 3 Core OptionsNewsJul.14,2025

-

Exploring the Versatility of H1Z2Z2-K 1X4mm2 Cables in Modern ApplicationsNewsJul.14,2025

-

Uses of Construction WiresNewsJul.14,2025

-

Types of Neoprene CableNewsJul.14,2025

Related PRODUCTS