1、 Concept

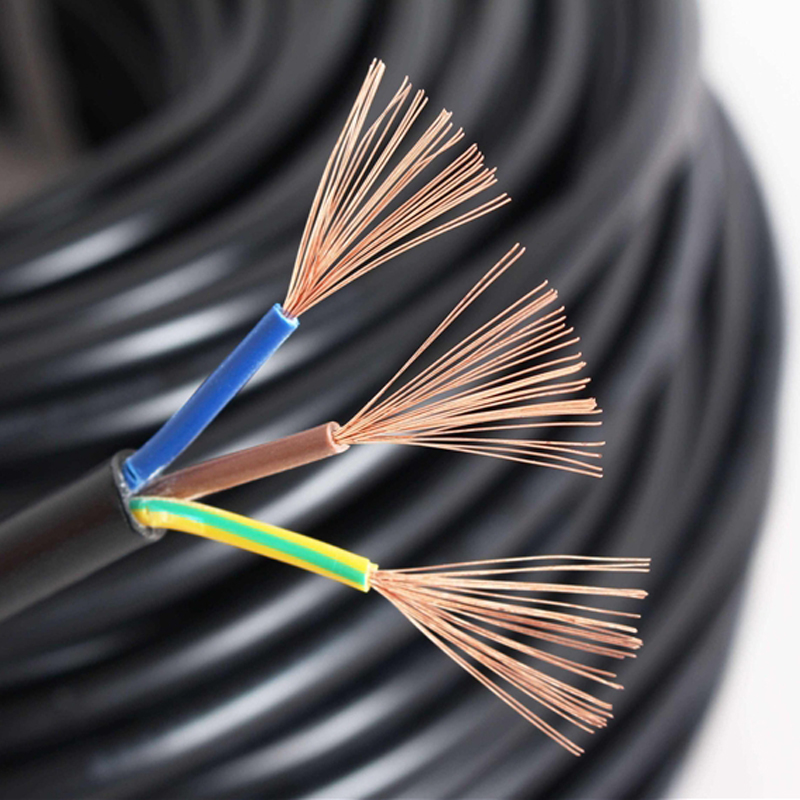

Cross linked cable usually refers to the cable insulation layer using cross-linked materials. The most commonly used material is cross-linked polyethylene (XLPE). The crosslinking process is that the linear molecular structure of polyethylene (PE) material is processed in a specific way to form a network structure of crosslinked polyethylene. The long-term allowable working mixed charge is increased from 700C to 900C (or higher), and the short-circuit allowable temperature is increased from 1400C to 2500C (or higher). On the premise of maintaining its original excellent electrical performance, the practical performance is greatly improved.

2、 Crosslinking process

At present, the production process of cross-linked cables in the cable industry can be divided into three types: the first type is peroxide chemical cross-linking, including saturated steam cross-linking, inert gas cross-linking, molten salt cross-linking and silicone oil cross-linking. The second type is dry chemical cross-linking in China; the second type is silane chemical cross-linking; the third type is irradiation cross-linking.

Inert gas crosslinking dry chemical crosslinking

Polyethylene insulation material with peroxide cross-linking agent is used to complete the extrusion of conductor shielding layer -- insulation layer -- insulation shielding layer by three-layer coextrusion, and then the cross-linking process is completed continuously and evenly through the sealed cross-linking pipe filled with high temperature and high pressure nitrogen. The heat transfer medium is nitrogen (inert gas), and the cross-linked polyethylene has excellent electrical properties. The production range can reach 500kV.

Silane chemical crosslinking -- warm water crosslinking

Polyethylene insulation material with silane crosslinking agent was used to complete the extrusion of variant shielding layer -- insulation layer -- insulation shielding layer by 1 + 2 extrusion method. The cooled insulated wire core was immersed in 85-950c hot water for hydrolysis crosslinking. The moisture content of insulation layer was affected by wet crosslinking. Generally, the highest voltage level is only 10kV.

21/35kV MEDIUM VOLTAGE XLPE INSULATED MULTI-CORE STEEL TAPE ARMOURED CABLE

Irradiation crosslinking -- physical crosslinking

The modified polyethylene insulating material is used to extrude the variant shielding layer insulating layer insulating shielding layer by 1 + 2 extrusion method, and then the cooled insulated wire core is evenly passed through the irradiation scanning window of the high energy electron accelerator to complete the cross-linking process. There is no crosslinking agent in the irradiated crosslinked cable material. During crosslinking, the high-energy electron beam generated by the high-energy electron accelerator effectively penetrates the insulating layer and produces crosslinking reaction through energy conversion. Because the electrons carry high energy and uniformly pass through the insulating layer, the crosslinked bond formed has high binding energy and good stability. The physical property of the cable is that the heat resistance is better than that of the chemical cross-linked cable. However, due to the limitation of accelerator energy level (generally no more than 3.0 MeV), the effective penetration thickness of electron beam is less than 10 mm. Considering the geometric factor, the voltage level of production cable can only reach 10 kV, and the advantage is less than 6 kV.

3、 Characteristics of radiation crosslinked cable

The aging life of cable insulation material mainly depends on its thermal aging life, which is determined by the rate of thermal oxidation, thermal cracking, thermal oxidative cracking, polycondensation and other chemical reactions occurring in the insulation material under heat. Therefore, the thermal aging life of insulation material directly affects the service life of cable. According to the chemical reaction kinetics derivation and artificial accelerated thermal aging test, the aging life of cable insulation material is determined The long-term allowable working temperature of the irradiated XLPE cable is:

Power cable YJV 0.6/1kv 1160c

If the rated working temperature is 1050C, the thermal aging life is more than 60 years.

If the rated working temperature is 900C, the thermal aging life is more than 100 years.

Overhead insulated cable jklyj 10kV 1220c

When overhead insulated cables are laid in the open air, the environmental and radiation resistance of insulating materials are more important. Radiation crosslinking insulation materials should be

After irradiation processing, it has good radiation resistance, and the radiation dose applied in the process of crosslinking has a great safety margin from the damage dose. The radiation damage dose of polyethylene is 1000kgy, while the processing dose is about 200kgy. With the improvement of the special formula, polyethylene is still radiation crosslinked in a wide range, so its performance will be improved in a long period of early use.

4、 Performance comparison of commonly used plastic insulated cables:

At present, the most commonly used insulating plastics in cable production are polyethylene and polyvinyl chloride, among which polyethylene has better electrical properties and better cross-linking property. Therefore, a variety of industrial cross-linking production processes, chemical cross-linking and irradiation cross-linking, have been developed. In addition to the performance shown in the table below, in the process of production and laying, the insulation layer of the commonly used cross-linked cables has higher hardness and strength (at room temperature), especially more difficult to peel than PVC insulation. Because of the best crosslinking performance, the highest degree of crosslinking and the highest peel strength of the irradiated XLPE cable. If the stripping of cross-linked cable insulation is relatively easy (similar to PVC), it must be that the degree of cross-linking is not enough or there is no cross-linking. Under normal circumstances, the crosslinking degree of the crosslinked cable produced by warm water crosslinking process is not enough. The reason is that the crosslinking degree of this kind of product is relatively low, and the crosslinking process is discontinuous and cannot be controlled automatically. It is greatly affected by human factors and is prone to under crosslinking.