Afrikaans Albanian Amharic Arabic Armenian Azerbaijani Basque Belarusian Bengali Bosnian Bulgarian Catalan Cebuano China Corsican Croatian Czech Danish Dutch English Esperanto Estonian Finnish French Frisian Galician Georgian German Greek Gujarati Haitian Creole hausa hawaiian Hebrew Hindi Miao Hungarian Icelandic igbo Indonesian irish Italian Japanese Javanese Kannada kazakh Khmer Rwandese Korean Kurdish Kyrgyz Lao Latin Latvian Lithuanian Luxembourgish Macedonian Malgashi Malay Malayalam Maltese Maori Marathi Mongolian Myanmar Nepali Norwegian Norwegian Occitan Pashto Persian Polish Portuguese Punjabi Romanian Russian Samoan Scottish Gaelic Serbian Sesotho Shona Sindhi Sinhala Slovak Slovenian Somali Spanish Sundanese Swahili Swedish Tagalog Tajik Tamil Tatar Telugu Thai Turkish Turkmen Ukrainian Urdu Uighur Uzbek Vietnamese Welsh Bantu Yiddish Yoruba Zulu

Jun . 26, 2024 17:07

Back to list

Comparing Overhead Cable Types Pricing and Characteristics

Understanding Overhead Cable Types and Their Quotes

In the realm of electrical power transmission, overhead cables play a pivotal role in delivering electricity from power plants to consumers. These cables, suspended high above the ground, are an essential component of our global energy infrastructure. However, selecting the right type of overhead cable is not just about picking the first one that comes along; it's a process that involves careful consideration of various factors, including technical specifications, environmental conditions, and cost implications.

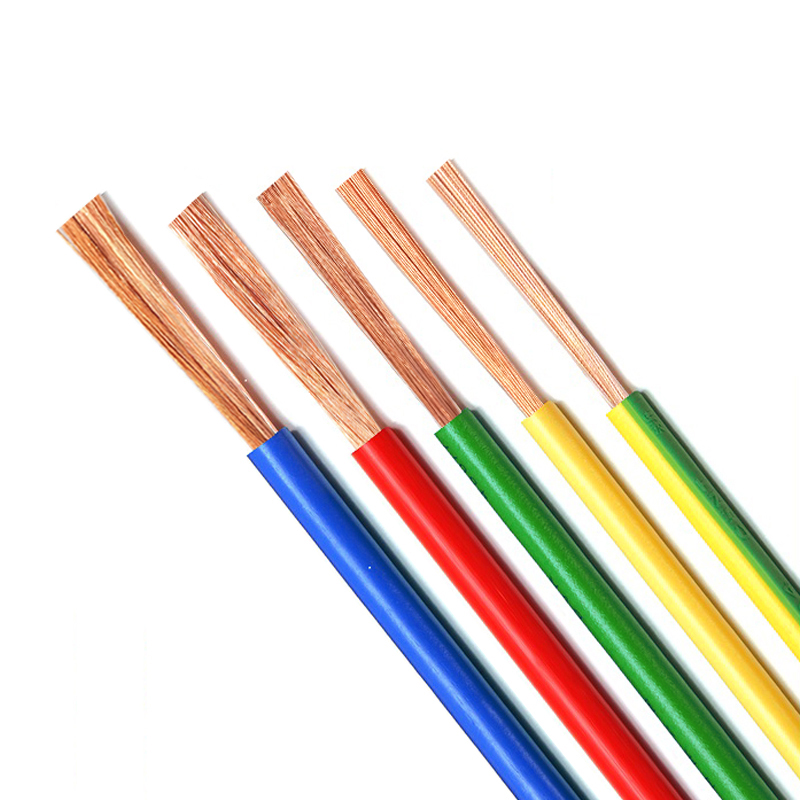

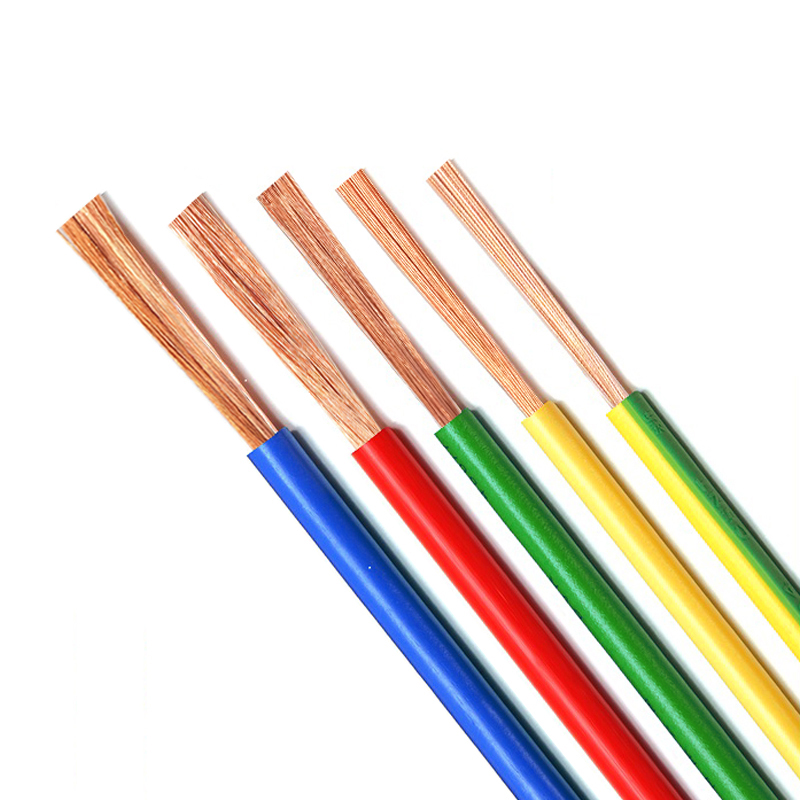

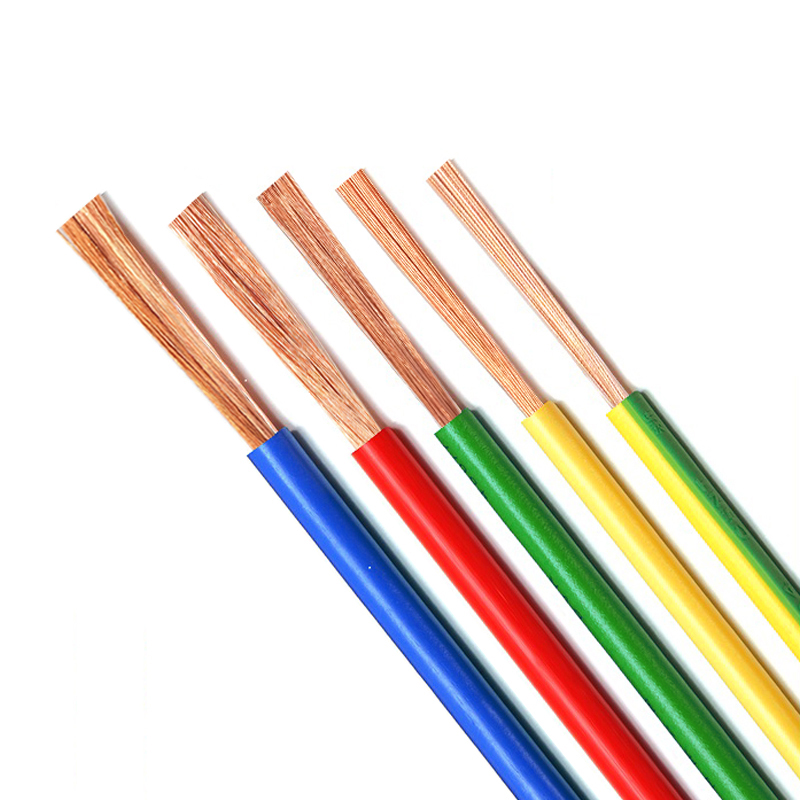

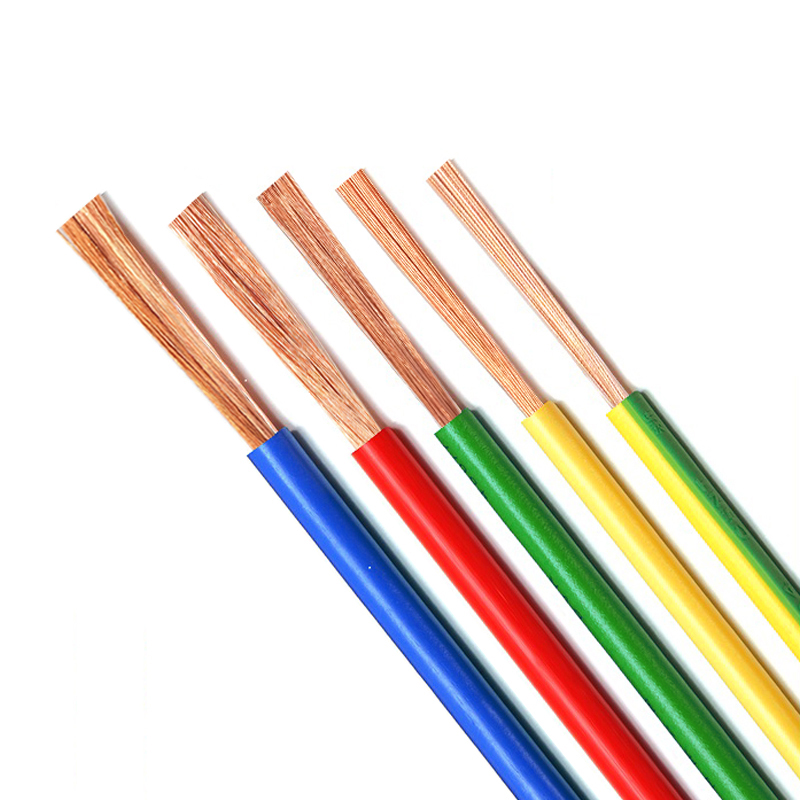

Overhead cables are primarily classified into two categories Aerial Bundled Cables (ABC) and Conventional Overhead Conductors. ABCs, as the name suggests, consist of multiple insulated conductors bundled together, offering advantages like reduced maintenance, improved safety, and lower installation costs. On the other hand, conventional overhead conductors, commonly made of aluminum or steel, are more traditional and widely used due to their high conductivity and durability.

When it comes to quotes for these cable types, several elements influence the pricing. The material composition of the cable, its ampacity (current-carrying capacity), and the length required are primary cost drivers. For instance, aluminum cables are generally cheaper than copper ones due to higher availability and lower cost of raw materials. However, copper has better conductivity, which might make it a more efficient choice in the long run.

Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables overhead cable type quotes. In areas prone to extreme weather conditions, such as heavy snow or strong winds, specialized cables designed to withstand these conditions may be necessary, leading to higher quotes. Additionally, the complexity of the installation, including terrain difficulty and accessibility, can significantly affect the overall project cost.

Moreover, safety features and technological advancements often come at a premium. For example, cables with anti-corrosion coatings or those equipped with advanced insulation materials for enhanced safety against electric shocks will typically have higher quotes.

Another aspect to consider is the warranty and after-sales service offered by the manufacturer or supplier. Quality assurance and prompt support can add value to the quoted price, ensuring reliability and reducing potential future expenses.

In conclusion, overhead cable type quotes are not merely about the upfront cost but involve a comprehensive evaluation of performance, resilience, and long-term efficiency. It's crucial for stakeholders to work closely with suppliers and engineers to understand the specific requirements, assess the associated costs, and make informed decisions that balance functionality and financial feasibility. Remember, the right overhead cable choice today can contribute significantly to a more efficient and reliable power transmission system tomorrow.

overhead cable type quotes. In areas prone to extreme weather conditions, such as heavy snow or strong winds, specialized cables designed to withstand these conditions may be necessary, leading to higher quotes. Additionally, the complexity of the installation, including terrain difficulty and accessibility, can significantly affect the overall project cost.

Moreover, safety features and technological advancements often come at a premium. For example, cables with anti-corrosion coatings or those equipped with advanced insulation materials for enhanced safety against electric shocks will typically have higher quotes.

Another aspect to consider is the warranty and after-sales service offered by the manufacturer or supplier. Quality assurance and prompt support can add value to the quoted price, ensuring reliability and reducing potential future expenses.

In conclusion, overhead cable type quotes are not merely about the upfront cost but involve a comprehensive evaluation of performance, resilience, and long-term efficiency. It's crucial for stakeholders to work closely with suppliers and engineers to understand the specific requirements, assess the associated costs, and make informed decisions that balance functionality and financial feasibility. Remember, the right overhead cable choice today can contribute significantly to a more efficient and reliable power transmission system tomorrow.

Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables

Environmental factors also impact the choice and pricing of overhead cables overhead cable type quotes. In areas prone to extreme weather conditions, such as heavy snow or strong winds, specialized cables designed to withstand these conditions may be necessary, leading to higher quotes. Additionally, the complexity of the installation, including terrain difficulty and accessibility, can significantly affect the overall project cost.

Moreover, safety features and technological advancements often come at a premium. For example, cables with anti-corrosion coatings or those equipped with advanced insulation materials for enhanced safety against electric shocks will typically have higher quotes.

Another aspect to consider is the warranty and after-sales service offered by the manufacturer or supplier. Quality assurance and prompt support can add value to the quoted price, ensuring reliability and reducing potential future expenses.

In conclusion, overhead cable type quotes are not merely about the upfront cost but involve a comprehensive evaluation of performance, resilience, and long-term efficiency. It's crucial for stakeholders to work closely with suppliers and engineers to understand the specific requirements, assess the associated costs, and make informed decisions that balance functionality and financial feasibility. Remember, the right overhead cable choice today can contribute significantly to a more efficient and reliable power transmission system tomorrow.

overhead cable type quotes. In areas prone to extreme weather conditions, such as heavy snow or strong winds, specialized cables designed to withstand these conditions may be necessary, leading to higher quotes. Additionally, the complexity of the installation, including terrain difficulty and accessibility, can significantly affect the overall project cost.

Moreover, safety features and technological advancements often come at a premium. For example, cables with anti-corrosion coatings or those equipped with advanced insulation materials for enhanced safety against electric shocks will typically have higher quotes.

Another aspect to consider is the warranty and after-sales service offered by the manufacturer or supplier. Quality assurance and prompt support can add value to the quoted price, ensuring reliability and reducing potential future expenses.

In conclusion, overhead cable type quotes are not merely about the upfront cost but involve a comprehensive evaluation of performance, resilience, and long-term efficiency. It's crucial for stakeholders to work closely with suppliers and engineers to understand the specific requirements, assess the associated costs, and make informed decisions that balance functionality and financial feasibility. Remember, the right overhead cable choice today can contribute significantly to a more efficient and reliable power transmission system tomorrow. Latest news

-

Reliable LIYCY Cable Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Premium Overhead Electrical Wire Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Innovative XLPE Electrical Cable Solutions for Modern Low and Medium Voltage NetworksNewsJul.14,2025

-

High-Quality Ethylene Propylene Rubber Cable – Durable EPDM Cable & 1.5 mm 3 Core OptionsNewsJul.14,2025

-

Exploring the Versatility of H1Z2Z2-K 1X4mm2 Cables in Modern ApplicationsNewsJul.14,2025

-

Uses of Construction WiresNewsJul.14,2025

-

Types of Neoprene CableNewsJul.14,2025

Related PRODUCTS