What Is The Meaning Of XLPE Insulated Cable?-ce certification 500 ft 12 thhn

What Is The Meaning Of XLPE Insulated Cable?

What Is The Meaning Of XLPE Insulated Cable?

The XLPE insulated cable short for cross-linked polyethylene insulated cables, are extensively utilized in the electrical sector due to their superior qualities when compared to PVC-insulated cables. XLPE refers to the cross-linking process that improves the thermal and mechanical properties of the insulation material, setting it apart from PVC insulation, known for its lower thermal resistance and flexibility. Understanding the significance, variances, and advantages of XLPE insulation over PVC cables is crucial for professionals to make well-informed choices regarding cable selection for specific projects. With experience in the electrical industry, I have often encountered inquiries about XLPE cables and their benefits over PVC insulation. This discussion aims to explore the meanings, distinctions, and advantages of XLPE insulated cables in comparison to PVC cables in a more engaging and informative manner.

The Meaning Of XLPE Insulated Cable Compared With PVC Cable

When compared to conventional PVC cables, XLPE (cross-linked polyethylene)--insulated cables mark a breakthrough in cable technology. A specific type of thermosetting polymer called cross-linked polyethylene goes through a chemical process to create a three-dimensional molecular structure, which improves the polymer's performance in demanding applications. Because of this procedure, XLPE cables have increased heat resistance and can sustain greater temperatures without deteriorating or deforming.

XLPE insulated cable offers superior resistance to chemicals and moisture, ensuring the cable's longevity and reliability even in harsh environments. The enhanced mechanical strength of XLPE enables these cables to withstand mechanical stress and pressure, reducing the risk of physical damage during installation and operation.

PVC (polyvinyl chloride) cables feature insulation made of a thermoplastic material that softens when exposed to heat and hardens upon cooling. While PVC cables are cost-effective and flexible, they lack their robustness and durability, particularly in challenging industrial settings where temperature variations and chemical exposure are common.

The products have become the preferred choice for various industrial applications due to their superior electrical performance, mechanical resilience, and resistance to environmental factors compared to PVC cables. The adoption of XLPE technology represents a significant advancement in cable insulation, ensuring reliable and efficient power transmission in diverse industrial scenarios.

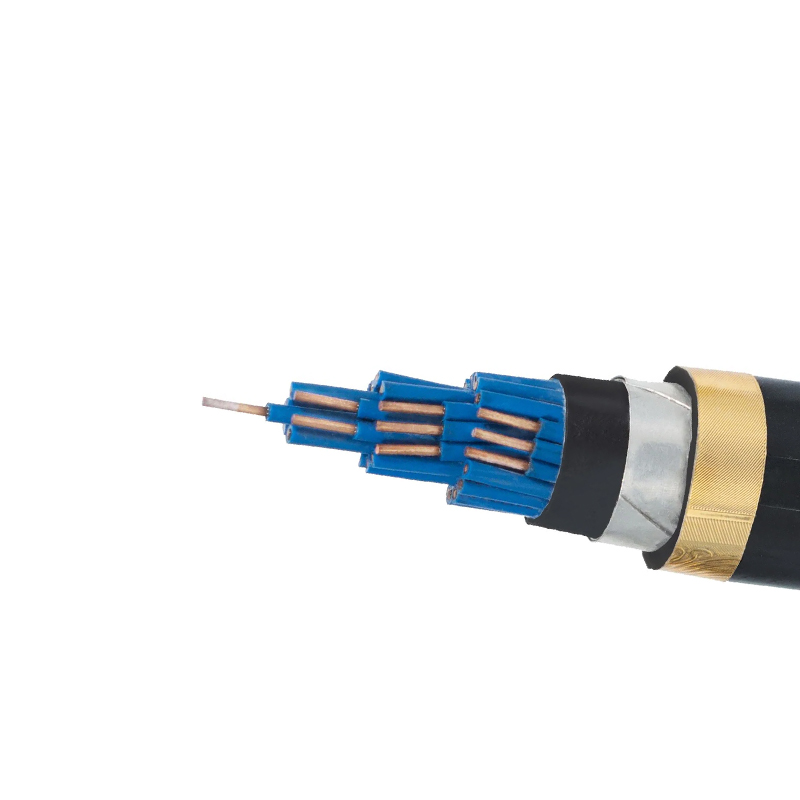

26/35kV MEDIUM VOLTAGE XLPE INSULATED MULTI-CORE STEEL TAPE ARMOURED CABLE

The Difference Between XLPE Insulated Cable And PVC Cable

The primary difference between PVC and XLPE cable insulation lies in their molecular structure and performance under different conditions. While PVC cables are known for their flexibility and cost-effectiveness, XLPE cables offer superior thermal stability, higher current carrying capacity, and better resistance to environmental factors such as moisture and chemicals. The molecular structure of XLPE insulation sets it apart from PVC insulation. While PVC is a thermoplastic material, XLPE undergoes a cross-linking process that transforms it into a thermosetting polymer. This cross-linking creates a three-dimensional molecular structure, providing XLPE cables with enhanced properties.

1. Thermal Stability:

The XLPE insulated cable exhibits superior thermal stability compared to PVC cables. XLPE can withstand higher temperatures without deformation or degradation. This makes XLPE cables suitable for applications where elevated operating temperatures are a concern, such as industrial settings or high-power transmission lines.

2. Current Carrying Capacity:

XLPE insulation offers a higher current carrying capacity than PVC insulation. The improved thermal properties of XLPE allow for reduced power losses and better heat dissipation, enabling XLPE cables to carry higher currents safely.

3. Environmental Resistance:

XLPE insulation provides better resistance to environmental factors such as moisture, chemicals, and UV radiation. XLPE cables are more resilient in harsh conditions, making them suitable for outdoor and underground installations where exposure to moisture or corrosive substances is likely.

4. Mechanical Strength:

While both XLPE and PVC cables are flexible, XLPE cables possess greater mechanical strength. They are better equipped to withstand mechanical stress, pressure, and impacts during installation and operation, reducing the risk of physical damage.

The product and PVC cables differ significantly in their molecular structure and performance characteristics. XLPE cables offer advantages such as superior thermal stability, higher current carrying capacity, and better resistance to environmental factors. PVC cables, on the other hand, are known for their flexibility and cost-effectiveness. Understanding these distinctions is crucial for selecting the appropriate cable insulation based on the specific requirements of each application.

Advantages Of XLPE Insulated Cables Compared With PVC Cables

The XLPE insulated cable offers several advantages over PVC cables, making them a preferred choice in various applications. One significant benefit of XLPE insulation is its superior ability to withstand high temperatures without degradation. The cross-linking process in XLPE molecules enhances thermal stability, ensuring reliable performance in demanding environments with temperature fluctuations.

Furthermore, XLPE insulation demonstrates lower dielectric losses, reduced water treeing effects, and enhanced resistance to electrical stress, contributing to improved overall cable performance and longevity. These properties make it particularly suitable for high-voltage power transmission and distribution systems where efficiency and reliability are paramount.

In addition to its exceptional electrical characteristics, XLPE insulation is environmentally friendly. Unlike PVC insulation, XLPE does not contain harmful substances such as lead or cadmium, aligning with the global shift towards sustainable and eco-friendly materials in the manufacturing industry. This eco-conscious feature of XLPE insulation enhances its appeal in projects where environmental considerations are a priority, promoting a greener approach to infrastructure development.

The product's exceptional thermal stability, improved electrical performance, and environmental friendliness make it a dependable and adaptable option for a variety of applications, including renewable energy projects and industrial power systems. By understanding the distinct advantages of XLPE insulation over PVC, professionals in the electrical industry can make informed decisions to ensure optimal performance and longevity in their installations.

In conclusion, its use of offers numerous advantages over traditional PVC cables, including superior thermal performance, enhanced durability, and environmental sustainability. As technology advances and industries evolve, the demand for high-quality XLPE cables is expected to grow steadily.

-

The Quantum Leap of XLPE Cable in Power DistributionNewsMay.29,2025

-

Mastering the Essentials of Building WireNewsMay.29,2025

-

Innovative Horizons of Rubber Trailing CablesNewsMay.29,2025

-

Exploring the Versatile World of Rubber CablesNewsMay.29,2025

-

Decoding the Mysteries of Building CablesNewsMay.29,2025

-

Advancements Redefining Control Cable TechnologyNewsMay.29,2025

-

Why It's Time to Replace Old Rubber CablesNewsMay.28,2025