What is XLPE Cable Insulation?-best pv jumper cables

What is XLPE Cable Insulation?

Introduction

In electrical engineering and cable manufacturing, XLPE (Cross-Linked Polyethylene) insulation stands out as a critical material, revolutionizing how we approach cable insulation. Employed extensively by XLPE cable manufacturing machines and recognized by cable machine manufacturers for its superior properties, XLPE insulation has become synonymous with high-quality cable production. This article aims to comprehensively understand XLPE cable insulation, its properties, applications, and why it's a preferred choice in the cable industry.

Basic Concepts of XLPE Insulation

Understanding XLPE begins with exploring what it is and why it's used in cable insulation.

Definition and Manufacturing Process

-

XLPE Explained: XLPE, or Cross-Linked Polyethylene, is a type of polyethylene that undergoes a cross-linking process, enhancing its thermal, mechanical, and chemical properties.

-

Manufacturing Process: The cross-linking of polyethylene is achieved through various methods like peroxide (chemical), silane (moisture cure), or irradiation. This process is integral in XLPE cable manufacturing machines, making them critical assets for manufacturers.

Characteristics of XLPE

-

Improved Thermal Properties: XLPE insulation can withstand higher temperatures than its non-cross-linked counterparts.

-

Enhanced Electrical Performance: It offers excellent dielectric strength, making it suitable for high-voltage applications.

-

Chemical and Physical Resistance: XLPE is resistant to chemicals, abrasion, and moisture, enhancing the cable's overall durability and lifespan.

This combination of properties has made XLPE a material of choice in high-performance cable insulation, particularly in applications demanding reliability under stress.

Advantages of XLPE Insulation in Cables

XLPE insulation offers several key benefits that make it a preferred choice in the cable industry, especially for XLPE cable manufacturing machines and manufacturers.

Superior Performance Attributes

-

High-Temperature Endurance: XLPE cables maintain integrity and performance at higher temperatures, making them suitable for various environments.

-

Longer Lifespan: Due to its robust properties, XLPE insulation has a longer lifespan than traditional insulation materials.

Versatility in Applications

-

Power Transmission: XLPE's high thermal and electrical resistance makes it ideal for power cables, particularly in high-voltage applications.

-

Underground and Underwater Cables: Its resistance to moisture and chemicals makes it suitable for harsh environments like underground or subsea installations

These advantages underscore why XLPE insulation is the material of choice for many cable machine manufacturers and is integral to modern cable design and production.

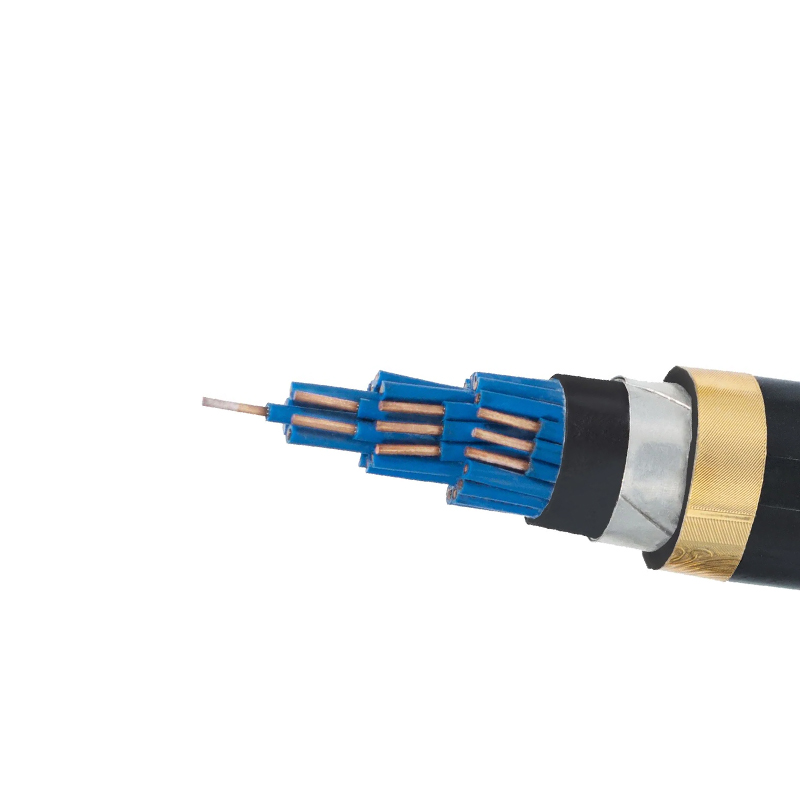

21/35kV MEDIUM VOLTAGE XLPE INSULATED MULTI-CORE STEEL TAPE ARMOURED CABLE

Technical Specifications and Standards

For XLPE insulated cables, adhering to technical specifications and industry standards is crucial for ensuring quality and safety.

Key Technical Specifications

-

Voltage Ratings: XLPE cables are available in various voltage ratings, suitable for different power transmission levels.

-

Insulation Thickness: The thickness of XLPE insulation is carefully calibrated based on the cable's intended use, balancing protection with flexibility.

Compliance with Industry Standards

-

International Standards: XLPE insulated cables must comply with international standards such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers).

-

Certifications: Ensuring that XLPE cables are certified by relevant authorities guarantees their reliability and safety in various applications.

This adherence to standards and specifications is a crucial focus for XLPE cable manufacturing machines and manufacturers, ensuring that the end products meet global quality benchmarks.

Installation and Maintenance of XLPE Insulated Cables

Indeed, ensuring optimal performance and longevity of XLPE insulated cables requires meticulous installation and ongoing maintenance. Attention to these aspects is crucial for harnessing the full benefits of these cables.

Installation Guidelines

-

Handling and Laying: XLPE cables require careful handling to prevent damage to the insulation. Special attention is needed while lying to avoid excessive bending or twisting.

-

Jointing and Termination: Given XLPE's specific properties, specialized cable jointing and termination techniques are required to ensure optimal functionality.

Maintenance Practices

-

Regular Inspections: Routine checks for any signs of wear or damage can help in the early identification of potential issues.

-

Environmental Considerations: While XLPE is robust, monitoring environmental factors that could impact the cable over time is essential.

Frequently Asked Questions

Addressing some common queries about XLPE cable insulation:

Can XLPE Insulated Cables Be Recycled?

-

XLPE insulation, due to its cross-linked nature, poses challenges in recycling. However, ongoing research and development are focused on making XLPE more recyclable.

How Does XLPE Compare to PVC Insulation?

-

XLPE excels over PVC in terms of thermal resistance, electrical properties, and durability, making it suitable for more demanding applications.

Conclusion

XLPE (Cross-Linked Polyethylene) cable insulation represents a significant advancement in cable technology. Its superior thermal and electrical properties and enhanced chemical and physical resistance make it an ideal choice for a wide range of cable applications. From power transmission to challenging environmental installations, XLPE stands out for its performance and reliability. For cable machine manufacturers and those operating XLPE cable manufacturing machines, understanding and harnessing the properties of XLPE is critical to producing high-quality, durable, and safe cables. As technology evolves, XLPE insulation plays a pivotal role in meeting the growing demands of various industries.

-

The Quantum Leap of XLPE Cable in Power DistributionNewsMay.29,2025

-

Mastering the Essentials of Building WireNewsMay.29,2025

-

Innovative Horizons of Rubber Trailing CablesNewsMay.29,2025

-

Exploring the Versatile World of Rubber CablesNewsMay.29,2025

-

Decoding the Mysteries of Building CablesNewsMay.29,2025

-

Advancements Redefining Control Cable TechnologyNewsMay.29,2025

-

Why It's Time to Replace Old Rubber CablesNewsMay.28,2025