Afrikaans Albanian Amharic Arabic Armenian Azerbaijani Basque Belarusian Bengali Bosnian Bulgarian Catalan Cebuano China Corsican Croatian Czech Danish Dutch English Esperanto Estonian Finnish French Frisian Galician Georgian German Greek Gujarati Haitian Creole hausa hawaiian Hebrew Hindi Miao Hungarian Icelandic igbo Indonesian irish Italian Japanese Javanese Kannada kazakh Khmer Rwandese Korean Kurdish Kyrgyz Lao Latin Latvian Lithuanian Luxembourgish Macedonian Malgashi Malay Malayalam Maltese Maori Marathi Mongolian Myanmar Nepali Norwegian Norwegian Occitan Pashto Persian Polish Portuguese Punjabi Romanian Russian Samoan Scottish Gaelic Serbian Sesotho Shona Sindhi Sinhala Slovak Slovenian Somali Spanish Sundanese Swahili Swedish Tagalog Tajik Tamil Tatar Telugu Thai Turkish Turkmen Ukrainian Urdu Uighur Uzbek Vietnamese Welsh Bantu Yiddish Yoruba Zulu

Apr . 09, 2024 15:27

Back to list

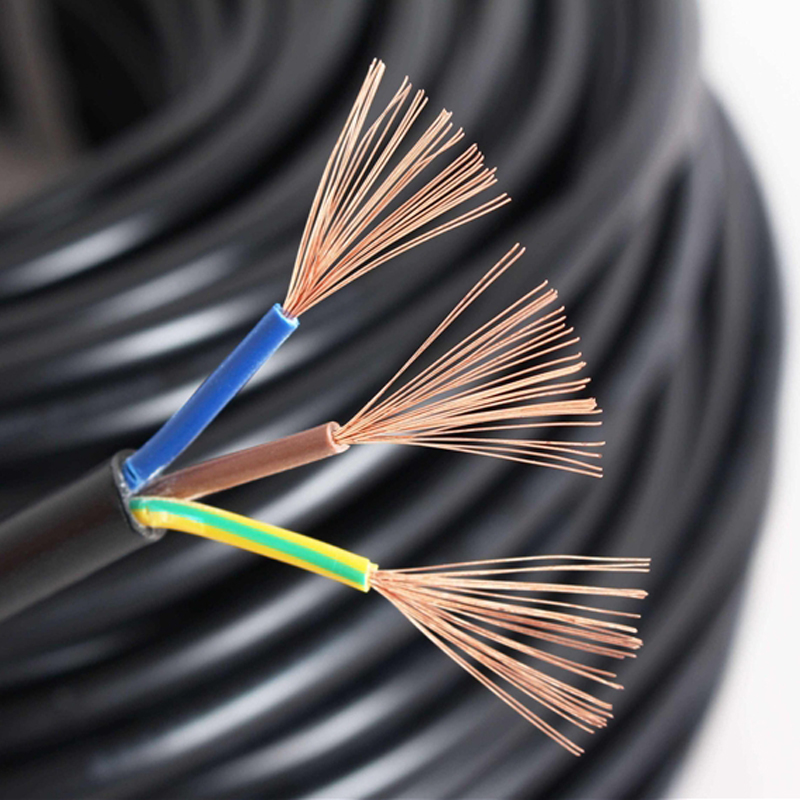

ce certification h5vv f-9 advantages of using polypropylene for medium-voltage cable insulation

Latest news

-

Reliable LIYCY Cable Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Premium Overhead Electrical Wire Solutions for Low and Medium Voltage ApplicationsNewsJul.14,2025

-

Innovative XLPE Electrical Cable Solutions for Modern Low and Medium Voltage NetworksNewsJul.14,2025

-

High-Quality Ethylene Propylene Rubber Cable – Durable EPDM Cable & 1.5 mm 3 Core OptionsNewsJul.14,2025

-

Exploring the Versatility of H1Z2Z2-K 1X4mm2 Cables in Modern ApplicationsNewsJul.14,2025

-

Uses of Construction WiresNewsJul.14,2025

-

Types of Neoprene CableNewsJul.14,2025

Related PRODUCTS